For professionals whose work involves the integration of sanitary fittings, the heat number plays a role of paramount importance. Understanding and appreciating the function of the heat number serves a range of purposes. It empowers industry decision makers and professionals to make better informed choices, helps to prove compliance to industry standards, enables reduction of hazards and instills confidence in products. Specifically, the heat number on sanitary fittings is the fundamental key to upholding quality on multiple fronts.

What Is a Heat Number?

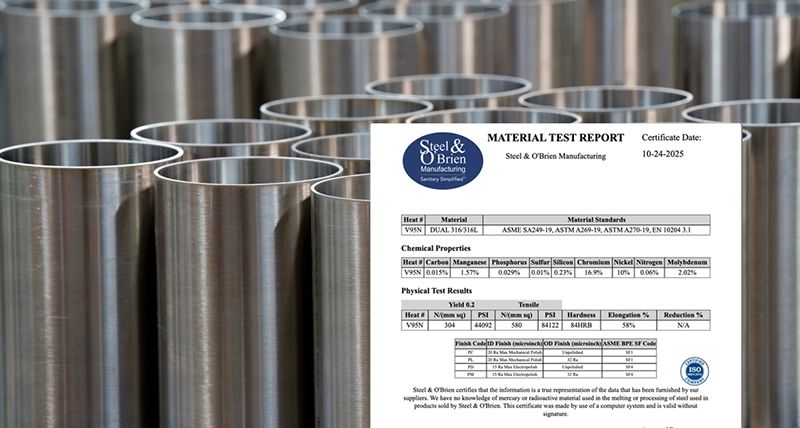

The heat number is a unique identifier that correlates a finished fitting to the batch of metal that was used to form it. In manufacturing, that traceability warrants that the product meets rigorous production and performance standards, as well as proffers confidence to members in the supply chain. As to what is the heat lot number, the term is used nearly interchangeably with heat number, signifying the origin lot of the material.

As such, heat numbers play a key role in maintaining integrity and safety. They guarantee that the material used meets the specifications promised, helping businesses stay compliant with industry regulations. Much more than a string of physical digits on a sanitary fitting, a heat number provides accountability. If questions arise later about performance or safety, it allows manufacturers and inspectors to track exactly where the material originated from.

Traceability is particularly important in industrial plumbing systems, where sanitary fittings will be connecting critical components. Without the assurance of a heat number, a company could face uncertainty about whether their materials truly meet the demands of sanitary environments, including the ability to withstand autoclaving, a commonly used means of sanitation for sanitary fittings.

Material Certification and Traceability

The certification process for sanitary fittings starts with verifying the material at the source. Each batch of metal is tested and documented, receiving a visible heat number before it ever reaches the factory floor. When that metal is later shaped into fittings, the number is carried along the chain, connecting the finished product to its origin.

Traceability protects product quality by ensuring that every fitting in use can be tied back to a verified batch. It also guarantees compliance with standards that demand proof of origin and chemical composition. Certification isn’t just a formality. It’s a guarantee that the sanitary fittings used in sensitive industries meet required specifications and won’t compromise safety or performance.

Sanitary and Industrial Fittings Standards

Meeting sanitary fitting standards means more than stamping a product with a number. It involves careful adherence to guidelines for cleanliness, durability and safety. Welding procedures, for example, must follow best practices to preserve the integrity of stainless steel and prevent contamination. Following these protocols ensures the final product remains compliant with both sanitary and industrial plumbing standards.

Industrial plumbing regulations are just as strict, demanding consistency across all materials and processes. By pairing heat numbers with reliable procedures, manufacturers create fittings that pass inspections and hold up under demanding use. Whether in food processing, pharmaceuticals or other industries, standards are met not by chance but by rigorous attention to detail.

Quality Assurance in Manufacturing

Heat numbers serve as a cornerstone of quality assurance. They make it possible to audit products, trace issues, and confirm that each fitting matches its certification. In a world where safety and performance are nonnegotiable, this layer of verification is indispensable.

Material certification adds another level of protection. By requiring documented proof of compliance, it strengthens the quality assurance process and helps catch issues early. For compliance officers, heat numbers and certifications are tools that keep companies aligned with standards while protecting customers and end-users. With robust traceability systems, they can monitor production from raw material to installation.

Manufacturing isn’t just about producing parts; it’s about building trust. Heat numbers on sanitary fittings represent that trust, showing a clear connection between product, process and standard.

Steel & O’Brien is proud to be your proven partner in precision and quality, delivering sanitary fittings engineered to meet the highest industry standards for compliance. Explore our full line of products today and see how proven traceability can make a difference in your operations.