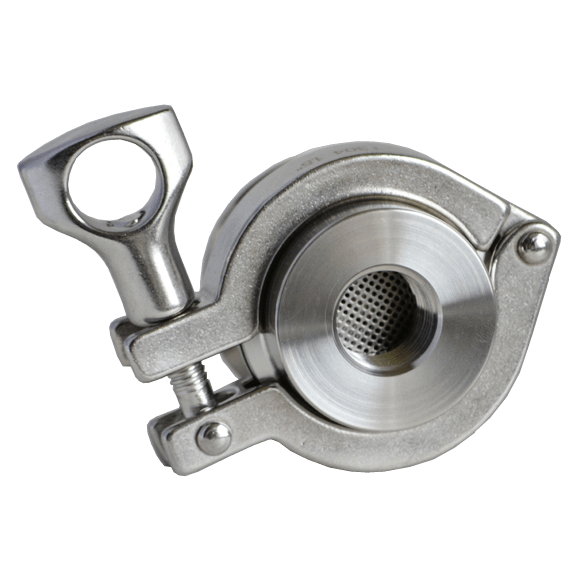

The TOP-FLO® 62-174R Air Blow Check Valves are designed to evacuate lines of product or CIP solution and for air agitation of product in tanks and other vessels. These valves help to protect pipelines against corrosion by drying process lines after they are cleaned and rinsed. Air drying of lines permits the formation of the protective oxide film. Air agitation thoroughly mixes and blends product – improving product uniformity and quality.

The Air Blow Check Valve can be used in any position, horizontal or vertical. They are easily installed on Ball check Valves or tanks by using a clamp, a gasket, and a mounting ferrule. No other fittings are required.

Features:

- Fail-Safe Operation – backflow of product or CIP solution prevented by simple air to open, spring to close operation.

- Easy Assembly/Disassembly – connections permit quick disassembly and assembly for replacing filter media, cleaning, or inspection. A quick couple or FNPT air connection.

- EPDM stopper.

- Clamp sizes 1-1/2” – 4″

- All 316L body construction.

- Remotely Controlled – can be remotely controlled by controlling the supply of air to the valve.

- Rugged Construction – spherical plug assembly is bonded EPDM rubber.

Specification:

Capacity to 1600 CFH air volume.

Click here for more information.